Compared to static gas blending methods, dynamic gas blending method not only provides high-flow mixed raw gases, but also allows obtaining the desired concentration of standard gases by adjusting the flow ratio between the raw gases and dilution gases. This method is particularly suitable for preparing low-concentration standard gases. In environmental air and exhaust gas monitoring, standard gases serve as the basis for testing methods, evaluating sampling efficiency, generating standard curves, calibrating analytical instruments, and conducting quality control in testing.

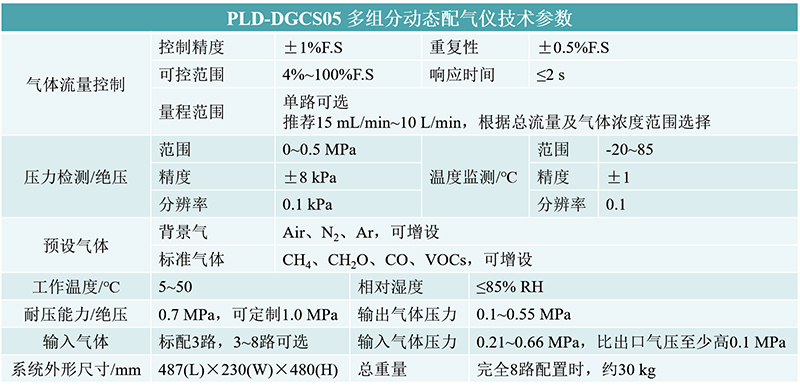

The PLD-DGCS05 Multi-Component Dynamic Gas Blending System adopts the mass flow blending method and can mix and dilute multiple raw gases with up to 8 gas paths. It can dynamically create target gas mixtures with specific gas ratios in real-time.

The PLD-DGCS05 Multi-Component Dynamic Gas Blending System is equipped with dual gas outlets. By using software controls, different gas outlets can be selected, enabling the separate or simultaneous output of target gas mixtures. The system also monitors the temperature and pressure of the mixed gas outputs, with each outlet capable of reaching an output pressure of up to 0.4 MPa.

Application Scenarios

Continuous flow, gas-solid phase reactions, and gas-liquid phase reactions that involve gases, such as photothermal catalytic CO₂ hydrogenation, photothermal catalytic CO hydrogenation, photothermal catalytic olefin or alkyne hydrogenation, photothermal catalytic methane dry reforming, photothermal catalytic reverse water-gas shift reaction, photocatalytic degradation of gas pollutants, photocatalytic partial oxidation of methane, photocatalytic methane coupling reaction, photothermal catalytic Sabatier reaction, photocatalytic nitrogen fixation, photocatalytic degradation of VOCs, etc.

The PLD-DGCS05 Multi-Component Dynamic Gas Blending System offers two operation modes: Simple Control Mode and Sequence Control Mode. It features a 7-inch touch screen for easy selection of different modes.

Simple Control Mode

The Simple Control Mode of the PLD-DGCS05 Multi-Component Dynamic Gas Blending System adjusts the gas flow rate and gas distribution of a single gas path to regulate the gas flow rate and composition at the gas outlets. This mode is suitable for dynamic gas blending scenarios where gas flow rate and composition remain constant over time, making it simple and suitable for most gas-solid phase reaction experiments.

Sequence Control Mode

The Sequence Control Mode of the PLD-DGCS05 Multi-Component Dynamic Gas Blending System allows setting different gas flow rates and gas distributions at different time points. This mode achieves controlled changes in gas flow rate and composition over time. The gas flow rate can change linearly along a timeline, and gas composition can be rapidly switched, enabling quick transitions of gas composition at the gas outlets.

Compatible Products

It can be used with the PLR-GSPR Atmospheric Gas-Solid Phase Photocatalytic Reaction System, PLR MFPR-I Multi-Functional Photocatalytic Reactor, and PLR-PTSRⅡ Photothermal Catalytic Reaction System to obtain mixed gases of specific concentrations, specific gas types, and specific humidity levels, meeting the demands of gas-solid phase photocatalytic reactions under complex gas conditions.

See the common gas correction coefficients in the article "Gas Flow Rate: Did You Set It Right?".

Note

When using toxic or harmful gases, strict protective measures must be taken, and the airtightness of each interface must be carefully checked. After gas blending, the gas paths should be purged with inert gas;

When corrosive gases are used, the gas type and concentration must be specified in advance, and the gases must be introduced through the designated inlet;

Each gas inlet must be equipped with a pressure reducing valve, and the gas source should be cut off when the system is not in use for an extended period;

All flow rates of the PLD-DGCS05 Multi-Component Dynamic Gas Blending System are indicated as values under standard conditions, where standard conditions are defined as 0°C and 101.325 kPa.