Have you ever encountered a situation where, when using the Labsolar-6A all-glass automatic online trace gas analysis system, the photocatalytic material clearly has photocatalytic activity, but the gas chromatograph does not produce peaks for a long time? Or, when creating a calibration curve, the gas chromatograph cannot detect the target substance?

What should we do to address the above gas chromatography issues and ensure that the experiment runs smoothly?

First, after the target gas generated by the photocatalytic reaction or the standard gas used for calibration curve (hereinafter referred to as the target gas) enters the Labsolar-6A all-glass automatic online trace gas analysis system, it is sent to the gas chromatograph through the all-glass online sampling/injection valve (Valve A). The process of sending the target gas into the gas chromatograph is performed by the carrier gas of the gas chromatograph, which sweeps the target gas from the quantitative loop of Valve A into the chromatographic column, and it enters the detector after separation. Only at this point can you see the peak of the target substance on the gas chromatograph. Therefore, the reason we cannot see the target substance peak may lie in the 6A or the gas chromatograph itself. Let's go through how to quickly troubleshoot step by step.

Figure 1. Schematic diagram of Labsolar-6A all-glass automatic online trace gas analysis system connected to a gas chromatograph.

1. Check the operation of the gas chromatograph

1.1 Check the carrier gas of the gas chromatograph

First, confirm whether the sub-pressure of the carrier gas cylinder connected to the gas chromatograph reaches 0.4~0.5 MPa, and then check whether the column front pressure of the gas chromatograph reaches the set value.

The column front pressure of the gas chromatograph refers to the operating pressure of the gas chromatograph. Only when the operating pressure reaches the preset value can the gas chromatograph work normally. Therefore, after confirming the sub-pressure of the carrier gas cylinder, it is necessary to determine the situation of the column front pressure of the gas chromatograph.

Regarding the specific numerical display, there may be differences between gas chromatographs from different manufacturers or models, and the display locations can be the pressure gauge on the gas chromatograph main unit, the display screen, or the gas chromatograph workstation. For specific viewing methods and pressure requirements, if you have any questions, please consult the corresponding gas chromatograph engineer.

At this point, please note:

① If the pressure decreases significantly after adjusting the carrier gas flow rate, it is recommended to replace the pressure reducing valve with a new one;

② Gas chromatographs produced by different manufacturers may have different sub-pressures for carrier gas cylinders. The pressure set by the on-site gas chromatograph engineer should be followed for daily experimental use, and the sub-pressure valve of the carrier gas cylinder should not be adjusted at will.

1.2 Check the detector of the gas chromatograph

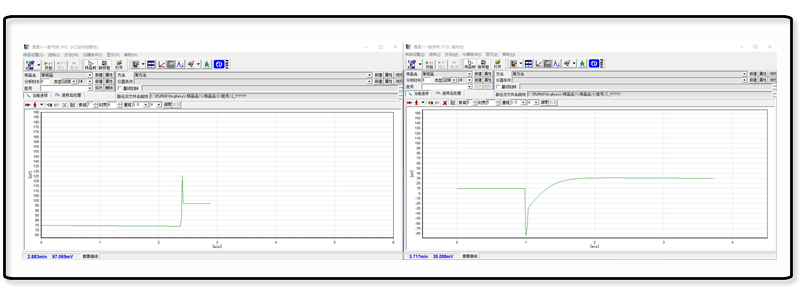

Check the operation of the detector by monitoring the signal value of the detector. Check whether the current is loaded for the TCD detector and whether the flame is burning for the FID detector, as shown in Figure 2.

Figure 2. Signal fluctuations after TCD loading (left) and signal fluctuations after successful FID ignition (right).

1.3 Check the temperatures of various modules of the gas chromatograph

Most gas chromatographs have a fault protection function. When a fault is detected in the gas chromatograph, it will automatically shut down the temperatures of various modules of the gas chromatograph by lowering the temperature to protect the gas chromatograph. Therefore, before use, confirm whether the temperatures of various modules of the gas chromatograph have reached the set temperature.

2. Check the operation of the Labsolar-6A all-glass automatic online trace gas analysis system

If the gas chromatograph is running normally, you can inject a certain amount of target gas into the gas chromatograph's sample inlet to check whether the Labsolar-6A all-glass automatic online trace gas analysis system is operating normally. If the gas chromatograph still does not produce peaks after injecting the target gas, it can be determined that the gas chromatograph is damaged and needs to be repaired by the corresponding gas chromatograph manufacturer. If the peak is normal, it may be necessary to maintain the Labsolar-6A all-glass automatic online trace gas analysis system.

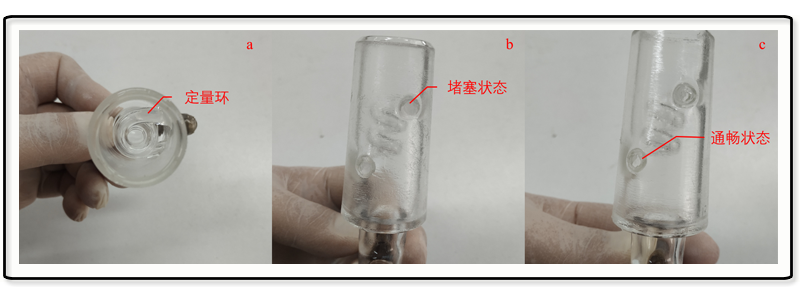

You can check if the quantitative loop is blocked!

Disconnect the carrier gas from the gas chromatograph and remove Valve A. Check if there is any vacuum grease blocking in the quantitative loop (see Figure 3). If the quantitative loop is blocked, it needs to be cleaned in time to ensure that the quantitative loop can sample the target gas properly, allowing the experiment to proceed normally.

Please note that regular and correct instrument maintenance is very important! For example, "Labsolar-6A Experimental Operation Procedure."

Figure 3. (a) Quantitative Loop (b) Valve Plug Status (c) Unobstructed Status

By following the above troubleshooting steps, you can quickly resolve more than 90% of chromatographic peak issues! If the issue cannot be resolved using the above methods, remember to contact Perfectlight Technology's after-sales service.